Given the competitive scenario in packaging solutions, pouch making machines have found place as an all-purpose and competent response to various requirements of packaging. These capabilities result in them being used to create specialized pouches for items such as food, pharmaceuticals, and cosmetics (and several others), which appeal onto the sales aspect of products either due to shape / composition or freshness. When looking to improve their packaging operations, businesses know they need nothing but the best from pouch machine manufacturers. In this pursuit, aspects like quality, innovation and sustainability are natural considerations very much in resonance with any specific needs of business.

Peak of Quality & Innovation

Superior quality and relentless innovation are the heart of any fruitful manufacturing collaboration. The best pouch machine manufacturers are not only able to meet but also exceed industry benchmarks. This business is investing heavily in research and development to bring more innovative pouch forming solutions for faster, closer tolerance & greater flexibility. Capabilities like advanced sensors for in-line quality assurance, AI-based predictive maintenance systems and modular design to enable customization/custom features upgrades unprecedented until today. These partnerships allow businesses to use pouch machines that not only improve productivity, but also enable packaging lines to adapt and change with the market.

Manufacturing Partners You Can Count On

The pouch machine manufacturer you choose is not just a supplier, they are a vital and committed part of your team that makes it ready to share the burden. The best partners provide full-service solutions from consultation and design customization, to assistance during set up/order installation as necessary and ongoing technical support in the long term. This brings a holistic view to your objectives and will guarantee that the change from existing equipment is as smooth possible if indeed problems do arise, those are addressed rapidly. Find manufacturers who have a history of delivering on time, under budget and with great customer service. An intense focus on training programs makes sure your team is comfortable running the machines and doing regular maintenance, helping you to still earn back our investment.

The Way in Which the Pouch Machine Manufacturers are Moldi...

This is no accident, the leading manufacturers of pouch machines are not just responding to industry trends; they are driving it. These first movers are catalyzing change by adopting sustainable practices, using smart automation and exploring eco-materials. They apply IoT and Industry 4.0 technologies to build energy-efficient machines with lower wastage levels for leveraging this data by providing real-time actionable insights that fuel process optimization decisions. Finally, they work with material suppliers to develop biodegradable and recyclable pouch alternatives - furthering the company's commitment on a global scale towards sustainability as well environmentally-conscious consumer packaging preferences. They influence moves beyond product offerings, impacting a greening of practices up and back down the supply chain.

Solutions Used For Pouch Making Machine Production Green

Sustainability has become a key business concept from something of an afterthought. The top band pouch machine such as TOM can afford these processes and features in green manufacturing practices with eco-friendly advantage. This consists of environmentally sustainable production facilities that use renewable energy sources, recycling programs for returned products and machines with environmental-friendly designs. Make sure the manufacturer has compliance certifications as discussed above (ISO 14001), if possible. Green Manufacturing partnerships align your brand with an eco-conscious for both the use of green manufacturing practices to reduce carbon footprint and as a means to define one component Corporate Social Responsibility profile.

Search for the Perfect Pouch Machinery Making Company to Accommodate Your Business

When looking into the decision of a pouch machine manufacturers, you need to be very sure on what are your industrial norms. Outline your production capacity requirements, what kinds of pouches you are looking to produce and if there is any specific feature(s) like child resistant or resealable closure that you would prefer. Plan ahead for scaling up, if your business does well you may need stronger machines to handle the load of increased production. You may also want to look into what after-sales support they provide, kind of warranty or guarantee is available as well parts and technical support turnaround time. Visiting trade shows, asking for demonstrations and speaking to existing customers are also part of the due diligence exercise in order to collect first-hand testimonials on how well (or not) a particular manufacturer is performing.

To summarize, the choice of the leading pouch machine manufacturer has ripples across your operations. Then, with the focus on quality, innovation, holistic collaboration and corporate stewardship (as-well-as fitting in your needs), you can establish a meaningful partnership that will allow you to evolve above "just getting by", setting the stage for not just surviving but excelling in today's competitive market.

EN

EN

BG

BG

CS

CS

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

HU

HU

TH

TH

MS

MS

GA

GA

BE

BE

KA

KA

EO

EO

LO

LO

NE

NE

MY

MY

KK

KK

MG

MG

SU

SU

GD

GD

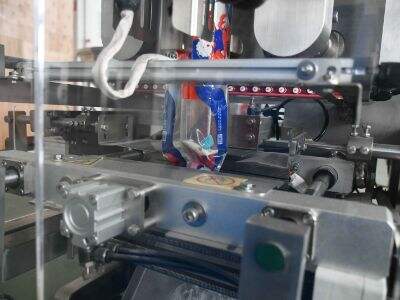

DXD Sachet Packaging Machine

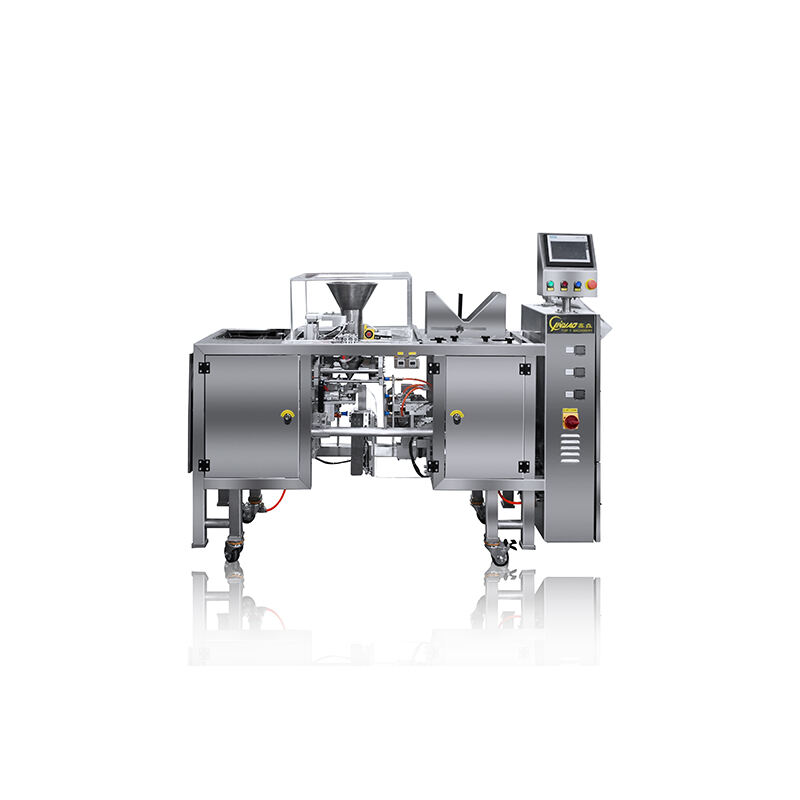

DXD Sachet Packaging Machine MDP Mini Doypack Machine

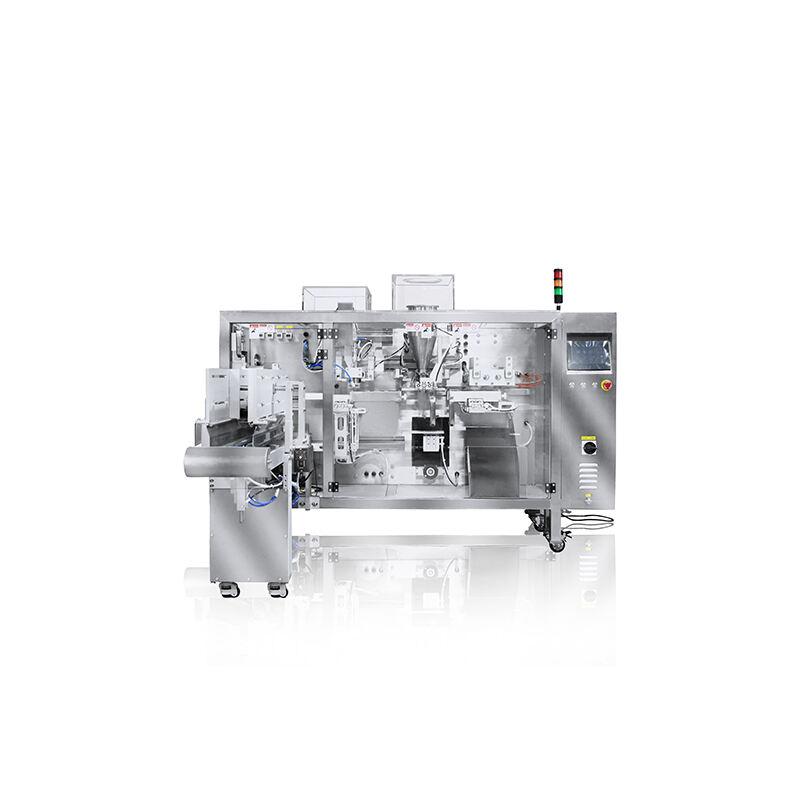

MDP Mini Doypack Machine MDPL Horizontal Premade Pouch Bagger

MDPL Horizontal Premade Pouch Bagger RPM Rotary Premade Pouch Bagging Machine

RPM Rotary Premade Pouch Bagging Machine VFFS Form Fill Seal Packing Machine

VFFS Form Fill Seal Packing Machine Auger Filler for powders

Auger Filler for powders Filling machine for liquids

Filling machine for liquids Linear weigher for granules

Linear weigher for granules Multihead weigher for granules

Multihead weigher for granules Acclivitous Belt Conveyor

Acclivitous Belt Conveyor Bowl conveyor

Bowl conveyor Collection table

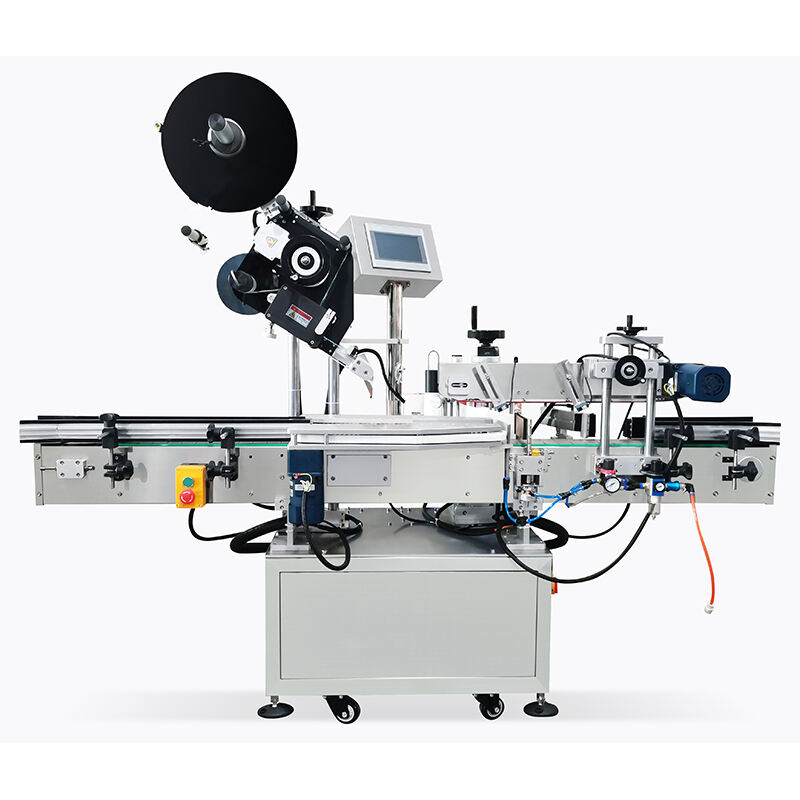

Collection table Labeling Machine

Labeling Machine Platform

Platform Screw Conveyor

Screw Conveyor Take-away conveyor

Take-away conveyor Z Type Bucket Elevator

Z Type Bucket Elevator Check weigher

Check weigher Metal detector

Metal detector Tunnel Metal detecting machine

Tunnel Metal detecting machine